- Phone: +86-534-26035861

- metals@bindingwire.net

- Home

- Concrete Reinforcing >

- PC Strand

Binding Wire Ties

Nails

Reinforcing Bars

Tools

PC (Pre-stressed Concrete) Stranded Wire for Reinforcement of Concrete Structures

We supply concrete reinforcing PC Wire Strands / wire ropes: Plain surface, Spiral ribs pc wire and Indented pc wire. Mainly for prestressed concrete structure reinforcement.

Application: Pc strand or pc wire is used in construction of large-span bridges on railway and highway, overhead crane beam, rock-soil anchoring Project, multi-storey industrial buildings, stadiums, coal mines.

Materials

Strand Wire compling with American Standards of 12.7 and 9.53 and British Standards of 12.5 and 9.3

Quality: Approved by Dubai Central Laboratory.

Wire Rope - 6 mm ( Steel Core & Galvanised.)

High carbon steel wire strand.

Strand size: 6.2mm-17.80mm.

Tensile strength: Grade from min.1470 N/mm2 to min.1960N/mm2

Zinc coating: ASTM A475 Class A

PC Wire Strand Technical Standard: ASTM A416, EN10138, BS 5896, AS 4671, ISO 6934, JISG 3536, GB/T5223, ASTMA421.

Packing: 2500-3500kg/coil or as per customer's requirement

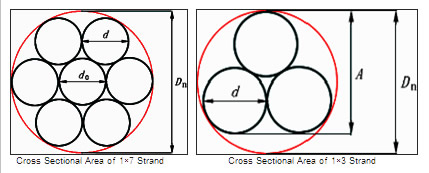

Structure: 1x19, 1x7, 1x3 & 1x2.

15.24 mm astm a416 grade 270 galvanized prestressed wire strand, for construction of bridges, subway, railway sleepers, poles, dams, nuclear power plants, high-rise buildings.

1x7 wire low relaxation, Dia 12.7 mm x 7 ply super grade LRPC Strand confirming to IS14268 - 1995

Product Variety

Smooth Pc Wire (Hard Drawn, Smooth Steel) Specification

| Nominal diameter (mm) |

Tolerance (mm) |

Tensile strength No less than (MPa) |

Off-proportion extension stress no less than (kN) |

Elongation no less than L0=200mm (%) |

Bending test | Relaxation value 1000h no more than | ||

| Times/ 180° No less than |

radius (mm) |

Ⅰ | Ⅱ | |||||

| 5.00 | ±0.05 | 1470 1570 1670 1770 |

1250 1330 1410 1500 |

4 | 4 | 15 | 8 | 2.5 |

6.00 |

±0.05 | 1570 1670 |

1330 1420 |

4 | 4 | 15 | 8 | 2.5 |

| 7.00 | ±0.05 | 1470 1570 |

1250 1330 |

4 | 4 | 20 | 8 | 2.5 |

Indented Pc Wire Specification

| Nominal diameter (mm) |

Tensile strength No less Than (MPa) |

Off-proportion extension stress no less than (kN) |

Elongation no less than L0=200mm (%) |

Bending test | Relaxation Value 1000h no more than |

||

| Times/ 180° No less than |

radius (mm) |

Ⅰ | Ⅱ | ||||

| ≤5.00 |

1470 1570 |

1250 1330 |

3.5 | 3 | 15 | 8 | 2.5 |

| >5.00 |

1470 1570 |

1250 1340 |

20 | ||||

Specification of Spiral Ribs Pc Wire(Sides Scratch Wire) (3-6 protruding ribs on the surface)

| Nominal Dia. (mm) |

Spiral ribs number (Item) |

Spiral ribs nominal size |

Retortion time (>=) |

|||

| Dia of base circle (D1) (mm) |

Dia of out profile (D) (mm) |

Single rib size |

Spiral rib length perimeter (C) mm/360° |

|||

| Width (a) (mm) |

Height (b) (mm) |

|||||

| 4.00 |

4 | 3.85±0.05 |

4.25±0.05 |

0.90-1.30 |

0.20±0.05 |

24.00-30.00 |

| 4.80 |

4 | 4.60±0.05 |

5.10±0.05 |

1.30-1.70 |

0.25±0.05 |

28.00-36.00 |

| 5.00 |

4 | 4.80±0.05 |

5.30±0.05 |

1.30-1.70 |

0.25±0.05 |

28.00-36.00 |

| 6.00 | 4 | 5.80±0.05 |

6.30±0.05 |

1.60-2.00 |

0.35±0.05 |

30.00-38.00 |

| 7.00 | 4 | 6.70±0.05 |

7.46±0.10 |

1.80-2.20 |

0.40±0.05 |

35.00-45.00 |

8.00 |

4 | 7.70±0.05 |

8.45±0.10 |

2.00-2.40 |

0.45±0.05 |

40.00-50.00 |

Special types: We also provide high quality zinc-5% aluminum-mischmetal alloy-coated steel wire strand, according to ASTM A855/A855M.Low Relaxation PC Steel Strand without galvanization also available.

Structures and Mechanical Properties

1×2 Structure PC Strand

| Strand Structure | Nominal Diameter | Strand Diameter Tolerance /mm |

Strand Reference sectional area Sn/mm2 |

Strand Reference quality per meter /(g/m) |

|

| Strand Diameter Dn/mm |

Wire Diameter d/mm |

||||

| 1×2 | 5.00 | 2.50 | +0.15 -0.05 |

9.82 | 77.1 |

| 5.80 | 2.90 | 13.2 | 104 | ||

| 8.00 | 4.00 | +0.25 -0.10 |

25.1 | 197 | |

| 10.00 | 5.00 | 39.3 | 309 | ||

| 12.00 | 6.00 | 56.5 | 444 | ||

1×3 Structure PC Strand

Strand Structure |

Nominal Diameter |

Strand Measurement A/mm |

Measurement A Tolerance /mm |

Strand Reference Sectional area Sn/mm2 |

Strand Reference quality per meter /(g/m) |

|

Strand Diameter Dn/mm |

Wire Diameter d/mm |

|||||

1×3 |

6.20 |

2.90 |

5.41 |

+0.15 -0.05 |

19.8 |

155 |

6.50 |

3.00 |

5.60 |

21.2 |

166 |

||

8.60 |

4.00 |

7.46 |

+0.20 -0.10 |

37.7 |

296 |

|

8.74 |

4.05 |

7.56 |

38.6 |

303 |

||

| 10.80 | 5.00 | 9.33 | 58.9 | 462 | ||

1×3 I |

12.90 |

6.00 |

11.20 |

84.8 |

666 |

|

8.74 |

4.05 |

7.56 |

38.6 |

303 |

||

1×7 Structure PC Strand

| Strand Structure | Nominal Diameter Dn/mm |

Diameter Tolerance /mm |

Strand reference sectional area Sn/mm2 |

Strand reference quality per meter/(g/m) | Center wire diameter (do) enlarged range/% not less than |

| 1×7 | 9.50 | +0.30 -0.15 |

54.8 | 430 | 2.5 |

| 11.10 | 74.2 | 582 | |||

| 12.70 | +0.40 -0.20 |

98.7 | 775 | ||

| 15.20 | 140 | 1101 | |||

| 15.70 | 150 | 1178 | |||

| 17.80 | 191 | 1500 | |||

| (1×7)C | 12.70 | +0.40 -0.20 |

112 | 890 | |

| 15.20 | 165 | 1295 | |||

| 18.00 | 223 | 1750 |

Mechanical Properties of 1x2 Structural Steel Strands

| Strand Structure | Strand nominal diameter Dn/mm |

Abstract tensile strength Rm/Mpa not less than | The largest force of the whole strand Fm/kN not less than | Rated non-proportional extension force | Total extension ratio at the largest force (Lo≥400)Agt/% not less than | Stress Relaxation | |

| Initial load equivalent to the percentage of the nominal largest force/% | After 1000h stress relaxation rate r/% not less than | ||||||

| 1×2 | 5.00 | 1570 | 15.4 |

13.9 | 3.5 | 60

70 80 |

1.0

2.5 4.5 |

| 1720 | 16.9 | 15.2 | |||||

| 1860 | 18.3 | 16.5 | |||||

| 1960 | 19.2 | 17.3 | |||||

| 5.80 | 1570 | 20.7 | 18.6 | ||||

| 1720 | 22.7 | 20.4 | |||||

| 1860 | 24.6 | 22.1 | |||||

| 1960 | 25.9 | 23.3 | |||||

| 8.00 | 1470 | 36.9 | 33.2 | ||||

| 1570 | 39.4 | 35.5 | |||||

| 1720 | 43.2 | 38.9 | |||||

| 1860 | 46.7 | 42.0 | |||||

| 1960 | 49.2 | 44.3 | |||||

| 10.0 | 1470 | 57.8 | 52.0 | ||||

| 1570 | 61.7 | 55.5 | |||||

| 1720 | 67.6 | 60.8 | |||||

| 1860 | 73.1 | 65.8 | |||||

| 1960 | 77.0 | 69.3 | |||||

| 12.00 | 1470 | 83.1 | 74.8 | ||||

| 1570 | 88.7 | 79.8 | |||||

| 1720 | 97.2 | 87.5 | |||||

| 1860 | 105 | 94.5 | |||||

| Note: Rated non-proportional extension force Fp0.2 is not less than 90% of the largest force of the whole strand | |||||||

Mechanical Properties of 1×3 Structural Steel Strands

| Strand Structure | Strand nominal diameter Dn/mm |

Abstract tensile strength Rm/Mpa not less than | The largest force of the whole strand Fm/kN not less than | Rated non-proportional extension force | Total extension ratio at the largest force (Lo≥400)Agt/% not less than | Stress Relaxation | |

| Initial load equivalent to the percentage of the nominal largest force/% | After 1000h stress relaxation rate r/% not less than | ||||||

| 1×3 | 6.20 | 1570 | 31.1 | 28.0 | 3.5 | 60 70 80 |

1.0 2.5 4.5 |

| 1720 | 34.1 | 30.7 | |||||

| 1860 | 36.8 | 33.1 | |||||

| 1960 | 38.8 | 34.9 | |||||

| 6.50 | 1570 | 33.3 | 30.0 | ||||

| 1720 | 36.5 | 32.9 | |||||

| 1860 | 39.4 | 35.5 | |||||

| 1960 | 41.6 | 37.4 | |||||

| 8.60 | 1470 | 55.4 | 49.9 | ||||

| 1570 | 59.2 | 53.3 | |||||

| 1720 | 64.8 | 58.3 | |||||

| 1860 | 70.1 | 63.1 | |||||

| 1960 | 73.9 | 66.5 | |||||

| 8.74 | 1570 | 60.6 | 54.5 | ||||

| 1670 | 64.5 | 58.1 | |||||

| 1860 | 71.8 | 64.6 | |||||

| 10.80 | 1470 | 86.6 | 77.9 | ||||

| 1570 | 92.5 | 83.3 | |||||

| 1720 | 101 | 90.9 | |||||

| 1860 | 110 | 99.0 | |||||

| 1960 | 115 | 104 | |||||

| 12.90 | 1470 | 125 | 113 | ||||

| 1570 | 133 | 120 | |||||

| 1720 | 146 | 131 | |||||

| 1860 | 158 | 142 | |||||

| 1960 | 166 | 149 | |||||

| 8.74 | 1570 | 60.6 | 54.5 | ||||

| 1670 | 64.5 | 58.1 | |||||

| 1860 | 71.8 | 64.6 | |||||

| Note: Rated non-proportional extension force Fp0.2 is not less than 90% of the largest force of the whole strand | |||||||

Mechanical Properties of 1×7 Structural Steel Strands

| Strand Structure | Strand nominal diameter Dn/mm |

Abstract tensile strength Rm/Mpa not less than | The largest force of the whole strand Fm/kN not less than | Rated non-proportional extension force | Total extension ratio at the largest force (Lo≥400)Agt/% not less than | Stress Relaxation |

|

| Initial load equivalent to the percentage of the nominal largest force/% | After 1000h stress relaxation rate r/% not less than | ||||||

| 1×7 | 9.50 | 1720 |

94.3 |

84.9 |

3.5 | 60

70

80 |

1.0

2.5

4.5 |

1860 |

102 |

91.8 |

|||||

1960 |

107 |

96.3 |

|||||

| 11.10 | 1720 | 128 |

115 |

||||

1860 |

138 |

124 |

|||||

1960 |

145 |

131 |

|||||

| 12.70 | 1720 |

170 |

153 |

||||

1860 |

184 |

166 |

|||||

1960 |

193 |

174 |

|||||

| 15.20 | 1470 |

206 |

185 |

||||

1570 |

220 |

198 |

|||||

1670 |

234 |

211 |

|||||

1720 |

241 |

217 |

|||||

1860 |

260 |

234 |

|||||

1960 |

274 |

247 |

|||||

| 15.70 | 1770 |

266 |

239 |

||||

1860 |

279 |

251 |

|||||

| 17.80 | 1720 |

327 |

294 |

||||

1860 |

353 |

318 |

|||||

| (1×7)C | 12.70 |

1860 |

208 |

187 |

|||

15.20 |

1820 |

300 |

270 |

||||

18.00 |

1720 |

384 |

346 |

||||

Note: Rated non-proportional extension force Fp0.2 is not less than 90% of the largest force of the whole strand |

|||||||